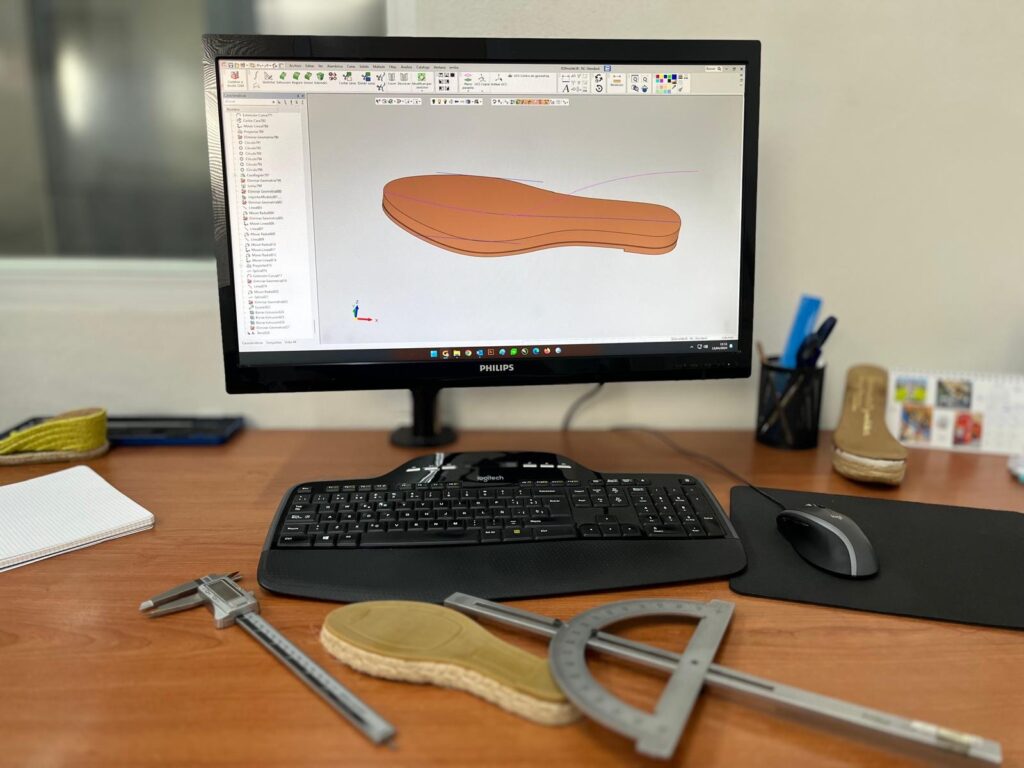

Manufacturing Process

The manufacturing process of espadrilles remains very artisanal and has remained almost unchanged over the last 50-60 years.

Despite this, we have incorporated some innovations to improve the accuracy and quality of the final product.

Our process begins with the only significant change over time: the transition from drawing models on paper or plaster molds to using them in computer programs and machining centers.

This modernization allows us to be more precise and efficient in design.

Having our own design department allows us to meet the specific needs of our customers and offer any model they can imagine, quickly adapting to market trends and demands.

This is how we manufacture our braids once the design is finalized.

6 steps

1 / Raw material

The first step in the manufacturing process is acquiring the highest quality jute thread, which we import from Bangladesh. This thread can be dyed or natural and comes in cones, ready for use in the subsequent steps of the process.

2/ Braiding

With these cones of thread, we begin the braiding process. Using machines originally adapted to make nets, we achieve a very characteristic jute braid. This process allows us to create braids in different sizes, shapes, and colors according to the design specifications.

3 / Warping process

Once we have the braid, we proceed to the warping process. This is a traditional method for forming the espadrille sole, in which the braid is wound around itself until the desired shape and size are obtained. This manual process ensures that each sole has the appropriate consistency and thickness.

4 / Sewing

With the sole already warped, we move on to the sewing process. Here, the sole is reinforced by threading it with jute thread, which gives it consistency and durability.

5 / braiding

The next step is the cutting or die-cutting of the rubber that will be placed on the base of the espadrille. The rubber is cut according to the type of sole and the size of the shoe, ensuring a perfect fit.

6 / vulcanization

Once we have all the parts, we move on to the vulcanization process. In a previously designed mold, the different parts are joined together using pressure and temperature. This process ensures a strong and durable bond between the sole and the upper part of the espadrille.

7/ Lining and gluing

Additionally, some models include a lined wedge to create the most well-known and traditional espadrille. This is the lining and gluing process, where the wedge and the sole are adhered to each other, providing an elegant and functional final finish. Each step of this artisanal process is carried out with great attention to detail and dedication, ensuring that each pair of espadrilles is not only comfortable and durable but also a unique piece of craftsmanship.